Civil Construction of Pearl River Delta Water Resources Allocation Project of Lot A2

Pearl River Delta, China

-

Project Type & Description: Water conservancy project, with designed water delivery flow of 80m3/s

-

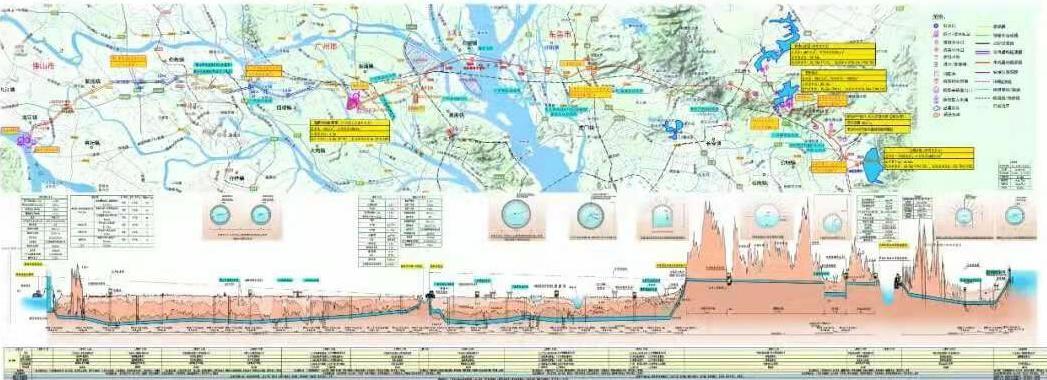

Total Length of Water Delivery Pipeline: 113.2 km, of which the total pipeline of lot A2 is 6.452 km

-

Depth: 40-60 m

-

Total Investment: CNY 35.4 billion (Approximately 5.057 billion USD)

-

Glodon Products Involved: BIM+GIS, Gsite, BIM+Smart Construction Site, Zplan

Water Conservancy Supports 9 Trillion Output with BIM and Smart Construction Site

Dongjiang River, as an important water source to support the economic and social development of the Pearl River Delta, supports the water consumption of 28% of the population and 48% of the GDP with less than 18% of the total water resources of the province. At present, the utilization rate of water resources in Dongjiang River has reached 38.3%, approaching the internationally recognized warning line of 40%.

This project helps to solve the contradiction between supply and demand of water resources in the Pearl River Delta, which not only solves the problem of water shortage in production and living in Guangzhou-Shenzhen-Dongguan regions, but also provides emergency water for Hong Kong and other places, and alleviates the problem of using ecological water in the Dongjiang River Basin. It also comprehensively guarantees the water supply security of the Guangdong-Hong Kong-Macao Greater Bay Area and provides strategic support for the sustainable and high-quality development of the Guangdong-Hong Kong-Macao Greater Bay Area. In addition, the underground deep-buried shield method is adopted for the Project. In the underground structure with a longitudinal depth of 40-60 meters, the ecological environment of the bay area is protected to the maximum extent, and valuable surface and shallow underground space are reserved for future development.

Details of Digital Applications

In this project, "BIM+GIS-based Data Integration Solution for Large-scale Water Conservancy Project in Full Life Cycle" is an excellent application case and one of the model solutions for intelligent water conservancy issued by the Ministry of Water Resources.

The information-based construction of the smart site in Lot A2 actively promotes the construction of smart supervision platform, including safety management, site management, digital site construction, smart supervision and other modules.

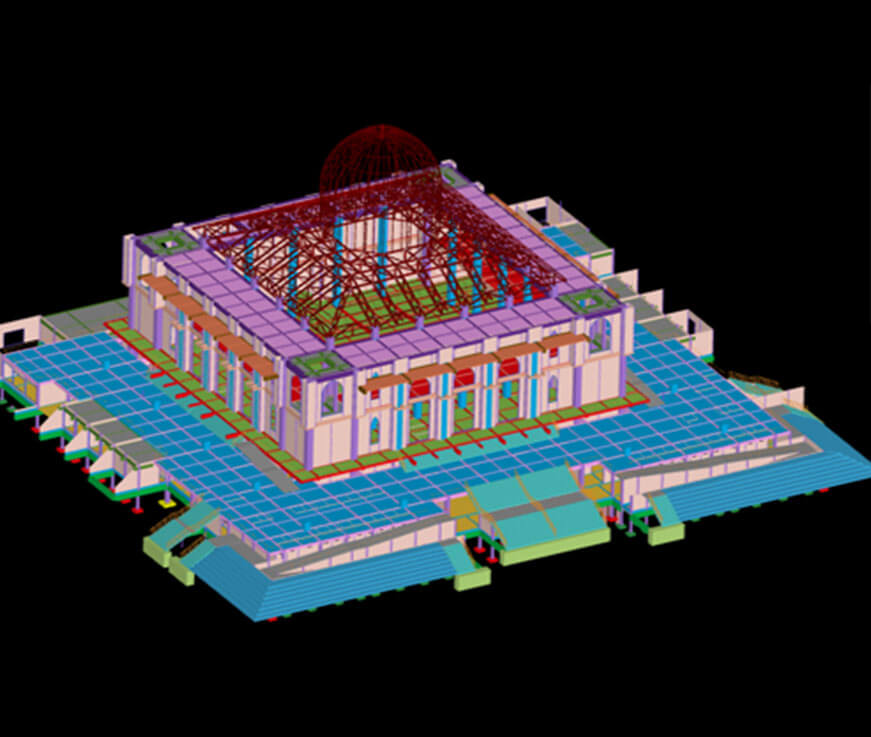

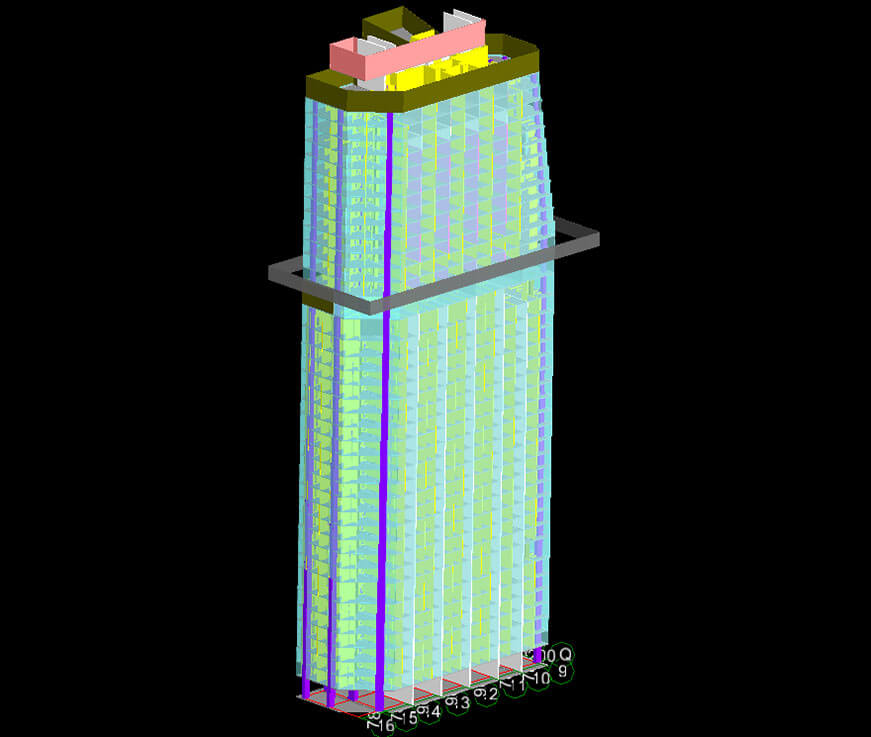

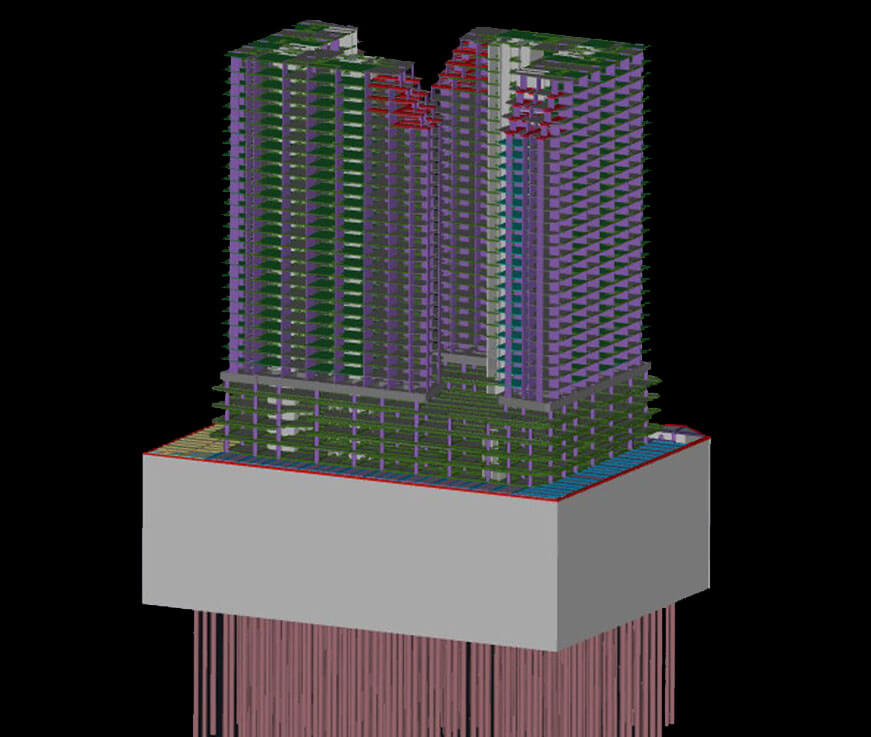

i. Implementation Scheme of BIM Technology Application

a. BIM Establishment and BIM Implementation

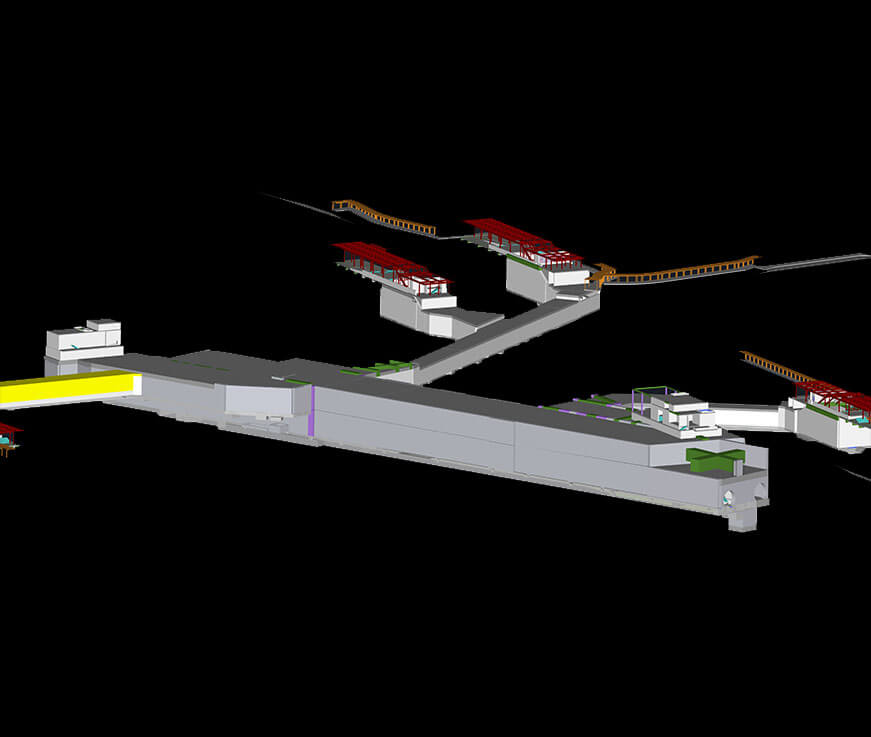

According to the project requirements, construction characteristics and site conditions, the Building Information Modeling (BIM) of the whole discipline of the Project is established completely, accurately and efficiently, so as to ensure the smooth coordination between construction quality and process to the greatest extent. Make each construction participant understand the design intention more intuitively, and provide basic data model for the subsequent stage.

b. Simulation and Comparison of Construction Progress

The site simulation schematic diagram integrates spatial information and time information into a visual 3D model by correlating BIM with the project construction schedule, which is conducive to intuitively and accurately reflecting the dynamic change process of the whole building construction.

c. Key and Difficult Construction Processes and Optimization Simulation

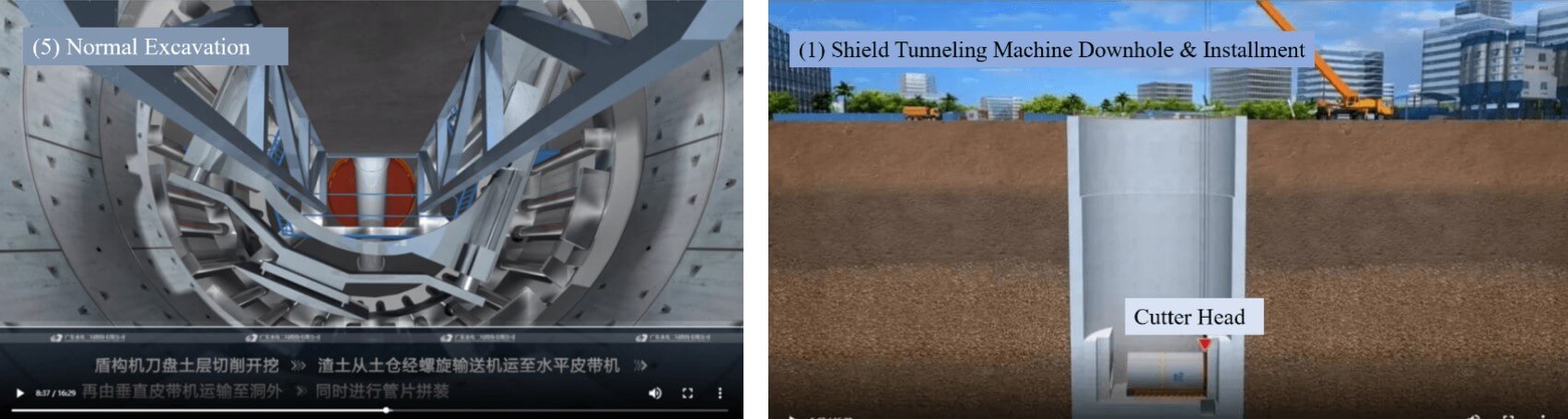

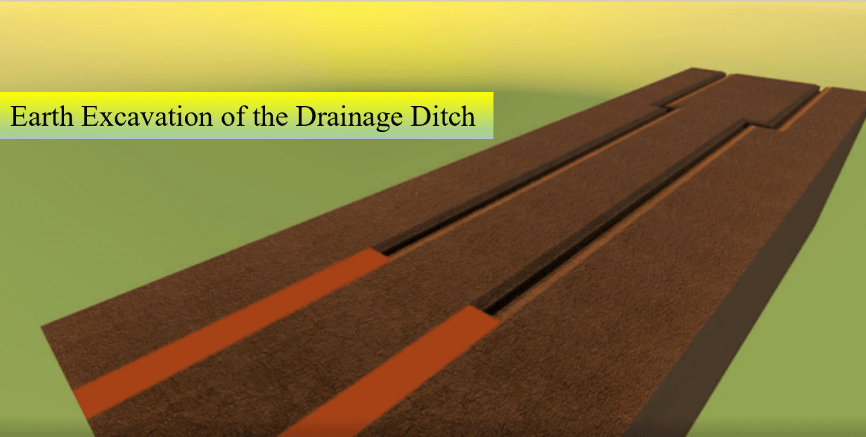

The simulation process of key and difficult construction processes includes personnel operation, equipment and facilities configuration and key process simulation. This is to eliminate construction hazards before formal construction.

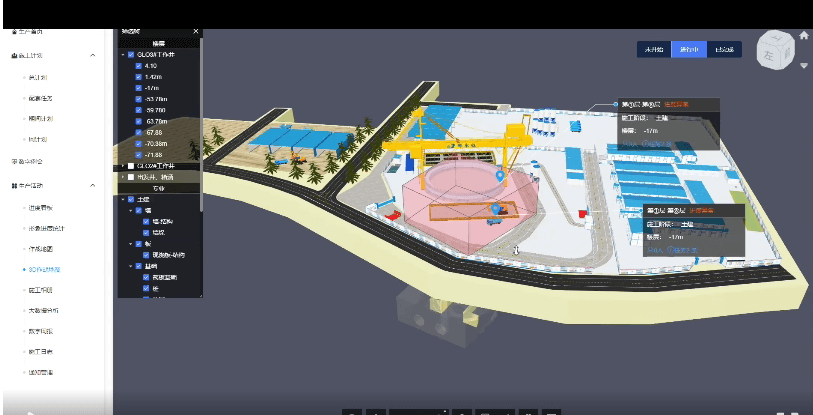

d. GIS Integration

Based on BIM+3DGIS fusion technology, build a technology-leading smart construction site information platform. GIS map module is based on 3D spatial information database, integrates image data, vector data and construction site physical model to provide visual construction site management services for management personnel. It can visually display geographical information, position, nearby road, facilities, environmental information and critical elements relating to the construction site so as to improve accuracy of the work and promote scientific management of the site, the space as well as facilities and equipment.

Based on BIM+3DGIS fusion technology, build a technology-leading smart construction site information platform. GIS map module is based on 3D spatial information database, integrates image data, vector data and construction site physical model to provide visual construction site management services for management personnel. It can visually display geographical information, position, nearby road, facilities, environmental information and critical elements relating to the construction site so as to improve accuracy of the work and promote scientific management of the site, the space as well as facilities and equipment.

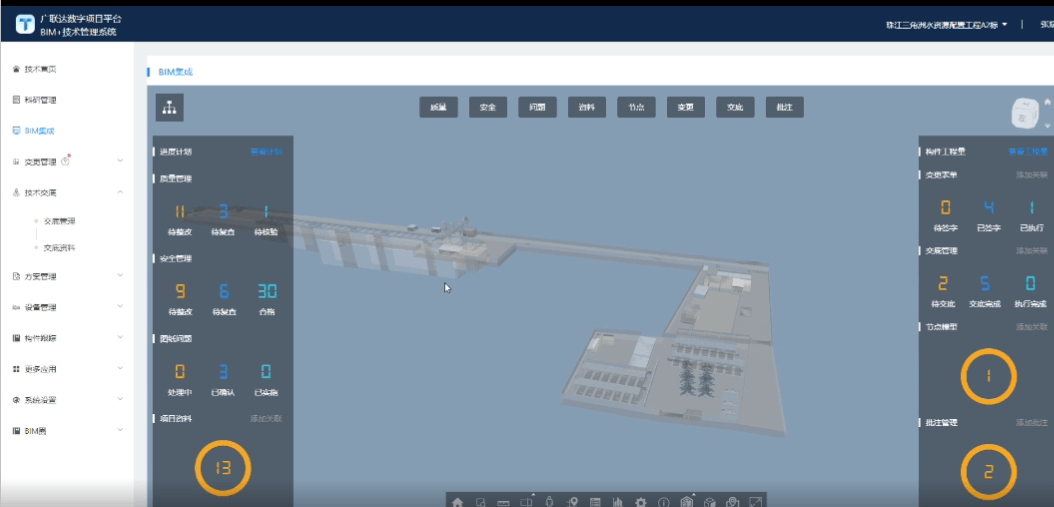

ii. Technical Management

a. Easy and Quick to Use

It can support at least 30 model formats, and assist to quickly browse files via websites and/or cellphones without any plug-ins being installed. It empowers a fast view of data and an accurate search of needed information.

It can support at least 30 model formats, and assist to quickly browse files via websites and/or cellphones without any plug-ins being installed. It empowers a fast view of data and an accurate search of needed information.

b. Three-Dimensional Disclosure

It can help to associate to photos, plans and audio/videos and fulfill a synchronous view of criteria, specifications and processes.

iii. Production Schedule Management

a. Production Management

The platform integrates a cloud management and control of BIM5D production schedule and cloud management of Zebra Progress and fulfills a dynamic control and regulation of the Project so as to cause the project schedule more controllable. Errors existing in the process can be timely disclosed and detected via the module which will contribute to taking probable measures and assurance of completion of the project as scheduled.

The platform integrates a cloud management and control of BIM5D production schedule and cloud management of Zebra Progress and fulfills a dynamic control and regulation of the Project so as to cause the project schedule more controllable. Errors existing in the process can be timely disclosed and detected via the module which will contribute to taking probable measures and assurance of completion of the project as scheduled.

b. Progress Management

The user, through statistical analysis, can visually find major elements affecting the progress, esp. those elements most frequently reminded by the pre-alert. The user, through the data tracking function, can check the scope of influence and probable measures so as to determine whether the construction progress is being affected or not. The recorded data will serve as a basis for negotiations and consultations relating to Party A, weather or any other force majeure factors affecting the construction progress.

The user, through statistical analysis, can visually find major elements affecting the progress, esp. those elements most frequently reminded by the pre-alert. The user, through the data tracking function, can check the scope of influence and probable measures so as to determine whether the construction progress is being affected or not. The recorded data will serve as a basis for negotiations and consultations relating to Party A, weather or any other force majeure factors affecting the construction progress.

iv. Application of Materials Management System

It can help record quantities of materials cart of the day or of the month, or the accumulated quantities and sum up weights recorded in the waybills and the actual weights. By visualizing weight loss of each cart, it can assist the responsible person to accept materials and make management decisions. Through inspection and acceptance of bulk materials and monitoring of disposed materials, material loss and improper disposal of wasted materials can be avoided.

It can help record quantities of materials cart of the day or of the month, or the accumulated quantities and sum up weights recorded in the waybills and the actual weights. By visualizing weight loss of each cart, it can assist the responsible person to accept materials and make management decisions. Through inspection and acceptance of bulk materials and monitoring of disposed materials, material loss and improper disposal of wasted materials can be avoided.

v. Application of Labor Management System

Entrance guard management system is based on the service real-name registration system which is fulfilled by using the IoT+Intelligent Hardware. Subcontractors enter the site and register with ID cards and labor contracts. Personnel information will be collected by hand-held equipment. Meanwhile, certificates and photos of special disciplines will be collected to ensure accuracy of personnel information and reduce workload of on-site staff. The system will automatically intercept the blacklisted personnel and those who do not meet requirements such as age, thus reducing the personnel-related risk of the project.

Entrance guard management system is based on the service real-name registration system which is fulfilled by using the IoT+Intelligent Hardware. Subcontractors enter the site and register with ID cards and labor contracts. Personnel information will be collected by hand-held equipment. Meanwhile, certificates and photos of special disciplines will be collected to ensure accuracy of personnel information and reduce workload of on-site staff. The system will automatically intercept the blacklisted personnel and those who do not meet requirements such as age, thus reducing the personnel-related risk of the project.

vi. Application of Intelligent Hardware

a.Visualization of Crane?

Using wireless networks or the 4G mobile network, the driver can stay in the cab, while the project manager can view the video image data in the office and on the cloud platform, so as to perform remote monitoring of the state of hook operation.

The system can store image information for 90 days, allowing the tracking of violation histories and the restoration of accidents.

The system can store image information for 90 days, allowing the tracking of violation histories and the restoration of accidents.

This application can resolve problems such as blind spots in crane drivers’ vision, blurred vision in long distance, error-prone voice guidance and so on. Since it can effectively prevent the occurrence of accidents, it is an effective way to improve construction efficiency and reduce safety accidents under new circumstances.

b.Safety Monitoring of Shield Machines

Shield machines commonly used in tunnel engineering can set up a safety monitoring system, and upload data in real time which will be accessed to the smart site platform.

Visual display of the general situation of the tunnel and shield machine will allow project managers to know the progress of shield machine tunneling and help to make suitable arrangements of construction tasks.

Managers can be notified of dynamic parameters of shield machines in real time and analyze whether the mechanical equipment is running normally. Managers can also monitor the guidance data of shield machines in real time, grasp the actual deviation timely, take practical measures and reduce quality accidents.

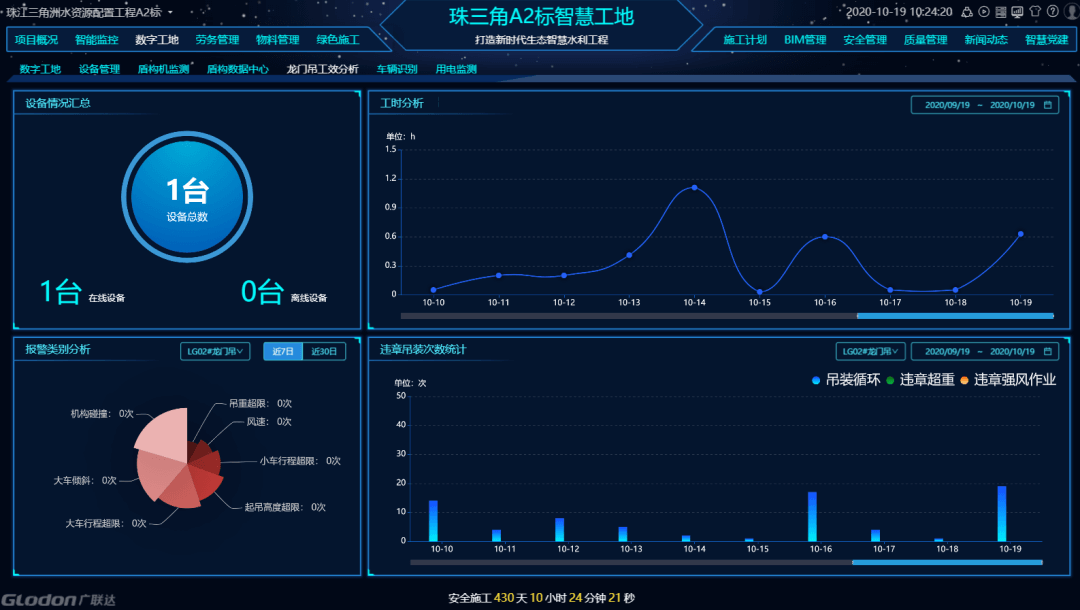

c. Safety Monitoring of Gantry Cranes

Through the smart site platform, online status of any equipment is displayed in real time, ensuring that gantry cranes are within the monitoring range, and preventing the dead angle in supervision caused by equipment communication interruption.

Through the monthly statistical chart of working hours and hoisting times, managers can optimize the construction arrangement of gantry cranes in a timely manner, reduce the idleness of gantry cranes, improve utilization efficiency, and serve as a reference for the salary settlement of gantry crane drivers.

Through the monthly statistical chart of working hours and hoisting times, managers can optimize the construction arrangement of gantry cranes in a timely manner, reduce the idleness of gantry cranes, improve utilization efficiency, and serve as a reference for the salary settlement of gantry crane drivers.

It can help check early warning situations for each gantry crane in detail, so as to allow the safety officers to carry out targeted management of special mechanical equipment and carry out safety education for drivers.

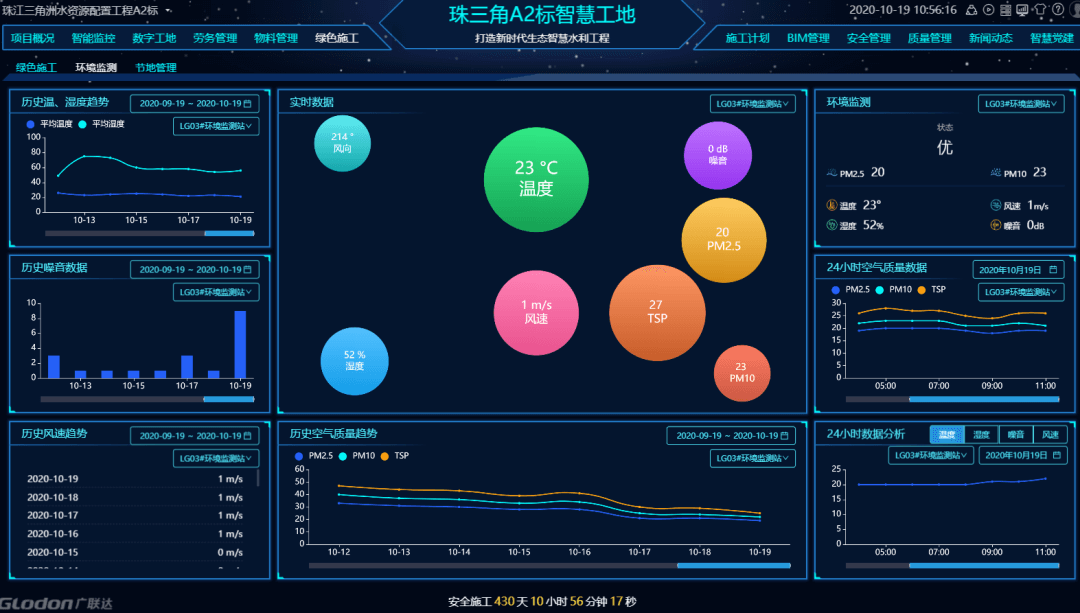

d. Environmental Monitoring System

Dust and noise monitoring is a site environmental monitoring service provided for construction sites, which conducts a real-time monitoring for data of PM10, PM2.5, particulate matter, temperature, wind speed and wind direction, and records the abnormal state by taking pictures. When the environment is determined to be abnormal by the system through monitoring, the management officers can spray into the air or onto the ground or through a fog gun, both manually or automatically so as to improve the construction environment.

Dust and noise monitoring is a site environmental monitoring service provided for construction sites, which conducts a real-time monitoring for data of PM10, PM2.5, particulate matter, temperature, wind speed and wind direction, and records the abnormal state by taking pictures. When the environment is determined to be abnormal by the system through monitoring, the management officers can spray into the air or onto the ground or through a fog gun, both manually or automatically so as to improve the construction environment.

e. Perimeter Intrusion Prevention System

Based on intelligent image identification technology, the perimeter intrusion system can effectively identify the nature of invasive materials by setting alert areas for surveillance videos and performing real-time perimeter intrusion analysis and cross-line detection. The alarm is smarter and more accurate.