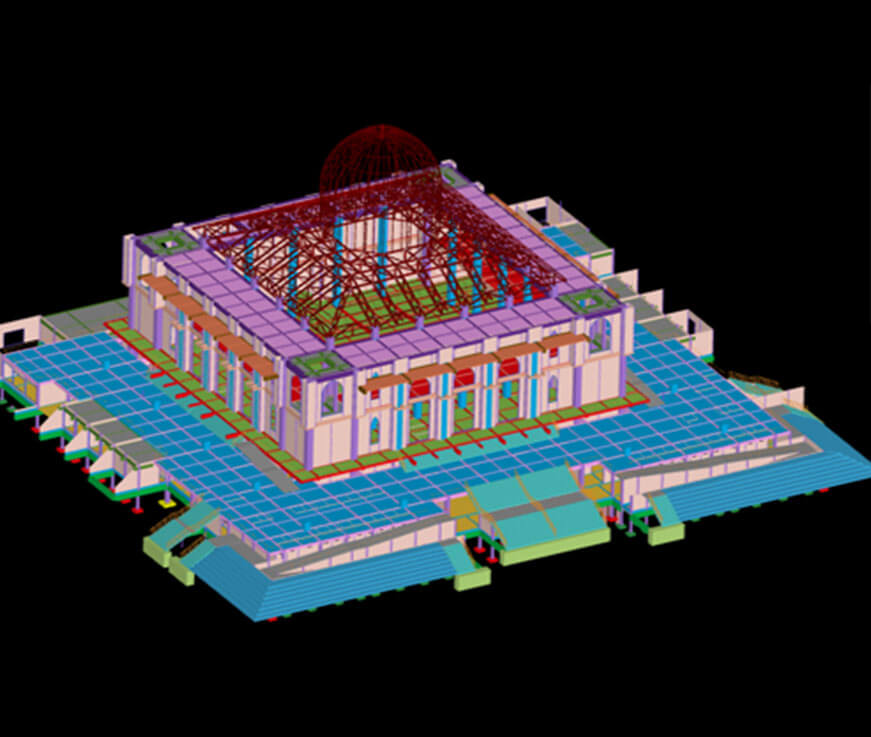

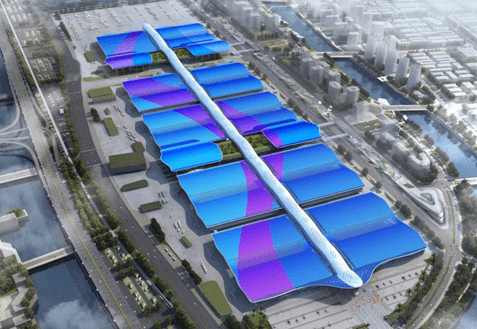

Shenzhen World Exhibition & Convention Center Project

Shenzhen, China

-

Project Type & Description: International Convention and Exhibition Center

-

Gross Floor Area: 1,580,000㎡

-

Main Contractor: China State Construction Engineering Corporation

-

Jointly Constructed by: China Construction First Group Corporation Limited, China Construction Third Engineering Bureau Group Co., Ltd., China Construction Steel Structure Corp., Ltd.

-

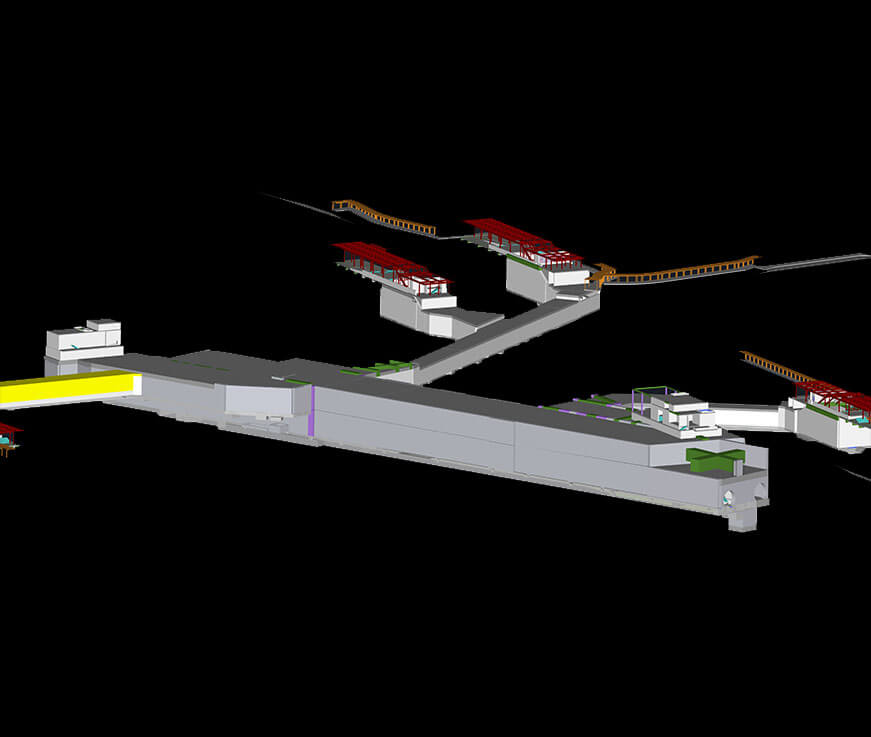

Glodon Products Involved: Giste, BIM+Smart Construction Site, Gwork Collaboration Platform

A Mega Project! Tremendous Smart Site in Shenzhen

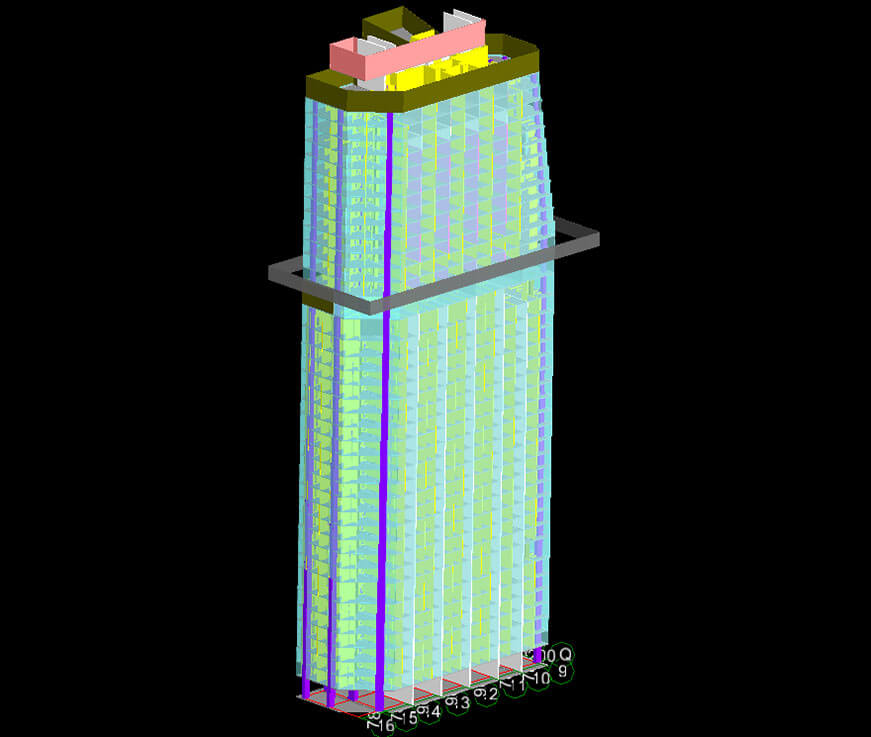

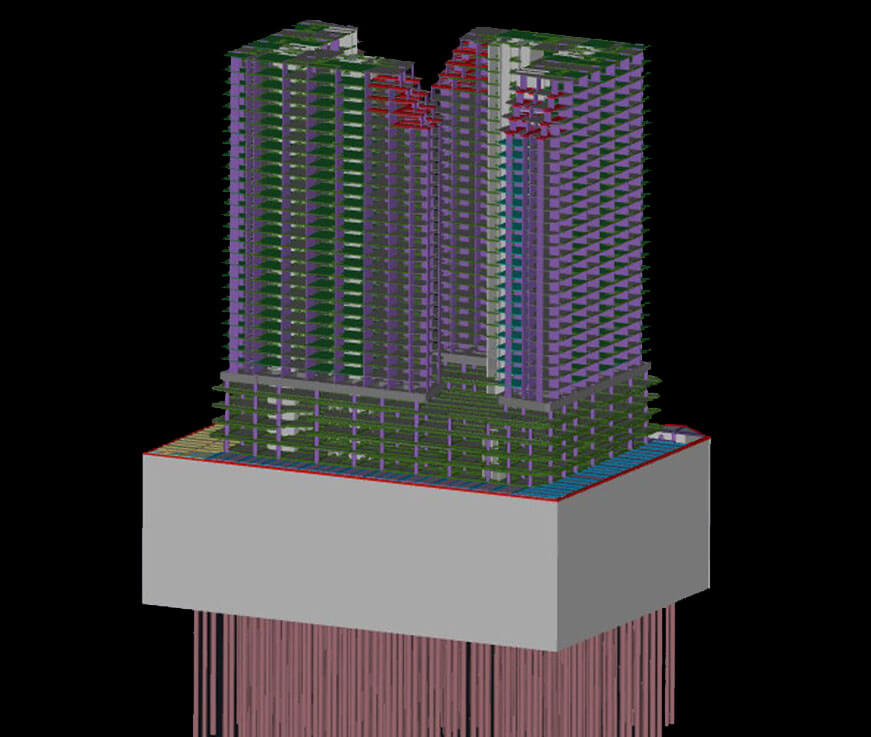

Shenzhen World Exhibition & Convention Center, a bright pearl located in the Guangdong-Hong Kong-Macao Greater Bay Area, has a total floor area of 1.58 million square meters. After completion, it will become the world's largest convention and exhibition center. The Project is characterized by a tough schedule, heavy workload, high standards and high pressure. The 7 construction areas are organized in parallel, with more than 3.6 million cubic meters of sludge earthwork excavated and transferred, 240,000 tons of steel structures installed, 400 sets of large construction machines and tools input, more than 15,000 tons of materials mobilized and transferred daily, and nearly 20,000 people input during the peak period.

This is a typical "Mega Project", which is an unprecedented challenge for the general contractor, CSCEC. Due to many difficulties in the Project, new requirements are put forward for quality management, schedule management, work safety and civilized construction management. It is necessary to establish a unified standard and improve the management and control level of all construction links, so as to achieve construction goals with high quality and efficiency.

This is a typical "Mega Project", which is an unprecedented challenge for the general contractor, CSCEC. Due to many difficulties in the Project, new requirements are put forward for quality management, schedule management, work safety and civilized construction management. It is necessary to establish a unified standard and improve the management and control level of all construction links, so as to achieve construction goals with high quality and efficiency.

Smart Site to Drive the Upgrade of Construction Process Management

The Project customizes a smart site management platform, which integrates the labor real-name management system, GPS positioning management system, material acceptance and weighing system, material tracking system, quality and safety inspection system, and Co-build platform system. In addition, UAV reverse modeling and thermal imaging technologies and TSP environmental monitoring system are used for intelligent management of the site. The Project Headquarters displays information dynamically in real time with a smart large screen, and combines with the BIM high-precision model built by the Project, so as to carry out intelligent construction management in a convenient and efficient manner.

The Project customizes a smart site management platform, which integrates the labor real-name management system, GPS positioning management system, material acceptance and weighing system, material tracking system, quality and safety inspection system, and Co-build platform system. In addition, UAV reverse modeling and thermal imaging technologies and TSP environmental monitoring system are used for intelligent management of the site. The Project Headquarters displays information dynamically in real time with a smart large screen, and combines with the BIM high-precision model built by the Project, so as to carry out intelligent construction management in a convenient and efficient manner.

Application Results of Smart Site Management Platform

i. ?Labor real-name registration system

During the peak period of the Project, there were nearly 20,000 people, a size equivalent to a small community with frequent mobility.

During the peak period of the Project, there were nearly 20,000 people, a size equivalent to a small community with frequent mobility.

Therefore, the Project needs to strictly implement labor? identification? system. Project managers and laborers shall set up personal files and bind their identification information immediately after entering the site. The system classifies and manages the personnel according to the rules to prevent the non-compliant personnel from entering the site. Access control systems are set in the office area, living area and construction area. The card is used for access, and relevant card statistical information is uploaded immediately. Managers can query in real time on the smart site platform of the Project, which is convenient for managers to control work type configuration and personnel operation on site.

After the laborers are registered, the system will automatically count the shift type of work, working day, working hour and other related data involved in each project stage, so that the relevant project leaders can know the working status of the subcontracting team at any time. In addition, through data analysis, the system will automatically warn about emergency situations such as overtime employment and dangerous operations, so as to avoid fatigue operation, and ensure and improve the safety of workers and the Project.

After the laborers are registered, the system will automatically count the shift type of work, working day, working hour and other related data involved in each project stage, so that the relevant project leaders can know the working status of the subcontracting team at any time. In addition, through data analysis, the system will automatically warn about emergency situations such as overtime employment and dangerous operations, so as to avoid fatigue operation, and ensure and improve the safety of workers and the Project.

ii.?Material tracking and acceptance system

IoT technology is used to automatically collect accurate data of on-site materials entering and leaving the site. It can not only carry out all-around lean management for commodities on the construction site, such as concrete, ready-mixed mortar, steel, flooring, cement, waste materials and other on-site materials frequently entering and leaving the site; it can also intelligently monitor cheating through the hardware around the weighbridge.

Data integration and cloud computing technologies are used to acquire first-hand data and effectively accumulate historical material data assets in a timely manner.

Internet and big data technologies are used to monitor the data of multiple projects and conduct full-dimensional intelligent analysis.

Mobile Internet technology is used to control the on-site situation and identify risks anytime and anywhere with a mobile phone.

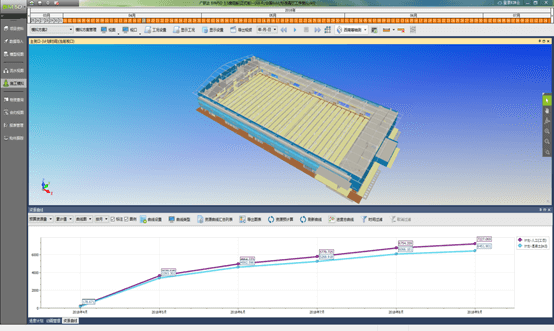

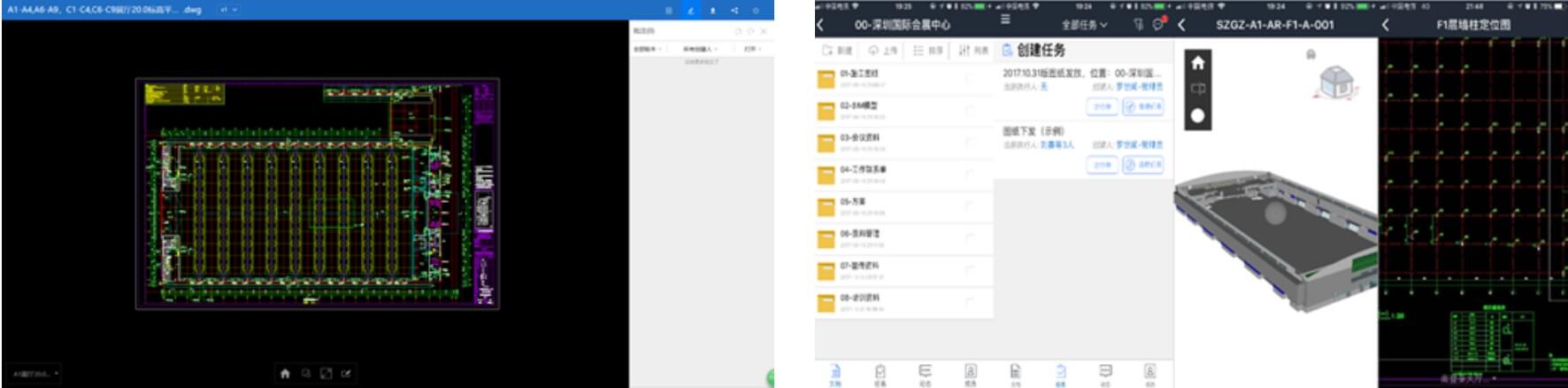

iii.?BIM5D schedule management makes tasks traceable

The construction period of the Project is tight, and multiple lines are constructed in parallel. BIM5D is used for schedule management with two main focuses.

The construction period of the Project is tight, and multiple lines are constructed in parallel. BIM5D is used for schedule management with two main focuses.

On the one hand, through background configuration, the BIM5D platform can push tasks to the mobile terminal of construction workers to complete a task assignment. At the same time, a large number of construction workers can also feed back the work completion to the background through the mobile terminal to provide actual progress reports.

The process, planned time and person responsible for the task can be set on BIM5D. By correlating construction tasks with construction technology, the foreman, technician and quality controller can quickly check the related process requirements of the task during on-site tracking, so as to arrange production tasks quickly and conveniently.

The foreman can acquire an overview of all flow sections assigned to him in the Production Schedule. After clicking on a flow section, the foreman can view all construction tasks covered by the flow section, and check the starting and ending time and progress details of a task, thus establishing a perfect mobile task tracking system.

The foreman can acquire an overview of all flow sections assigned to him in the Production Schedule. After clicking on a flow section, the foreman can view all construction tasks covered by the flow section, and check the starting and ending time and progress details of a task, thus establishing a perfect mobile task tracking system.

On the other hand, due to the large construction site, it is necessary to track on-site construction through UAV aerial photography. The fixed route shooting twice a week is not only convenient for all parties to understand construction progress in real time, but also accumulates a large amount of first-hand data of the Project for future use.

iv. ?Safety inspection system to prevent risks at the construction site

When on-site safety problems are found, the safety administrator can take photos of the problem points, describe the specific problems and upload them, and the system will send the problems to the project leader at the same time.

The system background will also summarize and statistically analyze the security problems, and formulate a security inspection report in one click.

When on-site safety problems are found, the safety administrator can take photos of the problem points, describe the specific problems and upload them, and the system will send the problems to the project leader at the same time.

The system background will also summarize and statistically analyze the security problems, and formulate a security inspection report in one click.

v.?Co-build data management system to facilitate collaboration

There are many versions of drawings, many model files, many construction participants and many types of materials submitted for approval. In order to facilitate unified and orderly management, a multi-party collaborative platform is required.

The Co-build platform can support the online previewing of more than 50 common file formats in the construction industry, without installing professional software. The files can be viewed on mobile phone or desktop anytime and anywhere, thus improving work efficiency.

Moreover, the collaboration platform also keeps the model files of each version entirely within the Project, and all changed versions are traceable.

Establishing an Application Model of "Digital Construction" in a "Mega Project"

Based on the successful application of BIM and smart site technology, the site is visible, manageable, controllable and measurable, and thus the management is upgraded.

Shenzhen World Exhibition & Convention Center Project has established a model of advanced application of "digital construction" in a "Mega Project". In the future, we will continue to drive the innovation and progress of the whole construction industry with advanced technology, realize the comprehensive management of digital, online and intelligent construction sites, and provide support for each project!